When your turbocharger fails, finding the right remanufacturing company can make all the difference between a smooth return to power and costly downtime. With so many options available, it’s not just about who can rebuild your turbo, it’s about who can do it right, fast, and with reliable support.

A quality turbo remanufacturing company combines technical expertise, precision parts, and efficient turnaround times to restore performance and protect your investment. In this guide, we’ll break down the key factors to consider when choosing a turbo remanufacturing partner, from quality assurance and turnaround speed to customer service and long-term reliability.

Understanding Turbo Remanufacturing

Before choosing a turbo remanufacturing company, it’s important to understand what remanufacturing really means and how it differs from a basic repair or full replacement.

Remanufacturing vs. Repair or Replacement

- Repair typically involves fixing or replacing only the failed component, which can leave other worn parts untouched and lead to future issues.

- Replacement means buying a brand-new turbocharger, which ensures reliability but often comes at a much higher cost.

- Remanufacturing, on the other hand, combines the best of both worlds. The unit is completely disassembled, inspected, and rebuilt to meet or exceed original equipment manufacturer (OEM) specifications. Every component is either refurbished or replaced with new parts, restoring the turbo’s performance and lifespan to like-new condition.

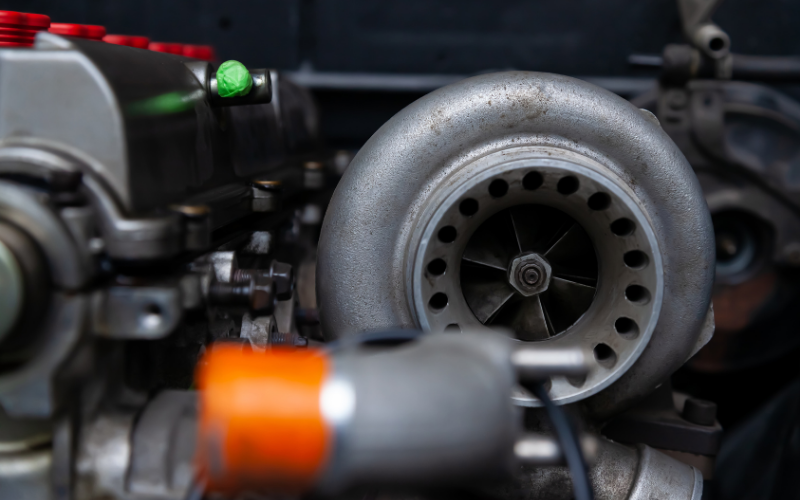

The Turbo Remanufacturing Process

A reputable remanufacturing company follows a detailed, multi-step process designed to ensure precision and reliability:

- Inspection: The turbo is fully disassembled and each component is inspected for wear, damage, and tolerances.

- Cleaning: Parts are thoroughly cleaned using specialized equipment to remove carbon, oil residue, and corrosion.

- Machining: Damaged or worn housings, shafts, and bearings are machined or replaced to restore OEM-level fit and finish.

- Balancing: The rotating assembly is dynamically balanced at high speeds to ensure smooth operation and prevent future failure.

- Testing: Each remanufactured turbo is tested for pressure, flow, and efficiency before it’s approved for use.

Benefits of a Remanufactured Turbo

- Cost Savings: You can save significantly compared to buying new, without sacrificing performance.

- Reliability: Because each part is inspected and rebuilt to OEM standards, remanufactured turbos perform as reliably as new ones.

- Sustainability: Remanufacturing reduces waste and the demand for new raw materials, making it an environmentally responsible choice.

What to Look for in Quality?

Not all turbo remanufacturing companies are created equal. The difference between a turbo that lasts and one that fails prematurely often comes down to the company’s commitment to precision, standards, and workmanship. Here’s what to look for when evaluating quality.

1. Precision and Testing

A high-quality remanufacturing process depends on accuracy at every step. The best companies use OEM-grade parts or genuine components that meet original specifications. Advanced equipment, such as high-speed balancing machines and flow benches, ensures each turbo performs exactly as it should under real-world conditions. Ask about the testing procedures used before the turbo leaves the facility; thorough testing is a strong indicator of professional standards.

2. Quality Control Standards

Look for companies that follow recognized quality management systems, such as ISO 9001 certification or equivalent standards. These certifications show that the company adheres to consistent procedures for inspection, documentation, and process control. Quality control isn’t just about the final product, it’s about ensuring every rebuild is performed with the same precision and accountability.

3. Experience and Expertise

Turbo remanufacturing is a specialized skill that takes years to master. Companies with experienced technicians, modern equipment, and a proven track record of successful rebuilds are more likely to deliver reliable, high-performance results. Check for signs of expertise such as factory training, manufacturer partnerships, or in-house engineering capabilities.

4. Warranty Coverage

A strong warranty speaks volumes about a company’s confidence in its workmanship. Look for coverage that protects against both parts and labor defects for a reasonable period, typically 6 to 12 months or more, depending on application and use. A detailed, transparent warranty not only safeguards your investment but also signals that the company stands behind its process and results.

Why Turnaround Time Matters?

When your turbocharger fails, time is more than money, it is performance, productivity, and peace of mind. Fast turnaround can mean the difference between minimal disruption and extended downtime.

The Impact of Downtime

For fleet operators, industrial machinery owners, or performance vehicle enthusiasts, every day a turbo is out of service can be costly. Trucks can’t make deliveries, equipment can’t run at full capacity, and vehicles can’t perform at peak levels. Choosing a remanufacturing company that prioritizes efficient service helps minimize these losses and keeps operations running smoothly.

Indicators of Efficient Operations

A company’s ability to deliver quickly often reflects its internal organization. Look for:

- In-stock components: Readily available parts reduce delays in assembly.

- Streamlined logistics: Efficient shipping and handling processes prevent bottlenecks.

- Clear scheduling and communication: Companies that provide realistic timelines and proactive updates typically meet them consistently.

Balancing Speed with Quality

Speed is important, but it shouldn’t come at the expense of precision or reliability. The best remanufacturers maintain rigorous testing and quality control while optimizing workflow. Ask about their process, how they manage turnaround without skipping critical inspections, balancing, or testing. A company that can rebuild turbos quickly and reliably demonstrates true operational expertise.

The Importance of Technical Support and Customer Service

Choosing a turbo remanufacturing company isn’t just about the product, it’s also about the people behind it. Reliable technical support and customer service can make the rebuild process smoother and help ensure long-term performance.

Expert Consultation Before and After Service

A knowledgeable team can guide you through the entire process, from selecting the right turbo for your application to troubleshooting post-installation issues. Pre-service consultation ensures the correct parts and procedures are used, while post-service support helps you maximize performance and longevity.

Responsiveness and Communication

Clear, timely communication is critical, especially when dealing with tight deadlines or complex builds. Companies that provide regular updates on progress, expected completion times, and any potential issues demonstrate professionalism and reliability. Responsive customer service ensures you’re never left guessing about the status of your turbo.

Ongoing Support for Troubleshooting, Installation, or Maintenance

Even after the turbo is back in your vehicle or equipment, questions can arise. Top-tier companies offer ongoing technical support for installation guidance, troubleshooting, or routine maintenance advice. This ongoing partnership protects your investment and helps prevent unnecessary downtime.

Common Red Flags to Avoid

Not every turbo remanufacturing company is worth trusting. Being able to spot warning signs early can save you from costly mistakes and unreliable service. Here are some common red flags to watch for:

Unrealistically Low Prices or Vague Service Descriptions

If a quote seems too good to be true, it probably is. Extremely low prices may indicate substandard parts, shortcuts in the rebuild process, or inadequate testing. Similarly, vague service descriptions that don’t detail the process, parts, or testing methods can be a sign that quality isn’t a priority.

Lack of Testing or Warranty Information

A reputable remanufacturer should clearly explain their testing procedures and offer a warranty that protects parts and labor. Companies that don’t provide this information may be cutting corners, which could lead to premature failure or hidden defects.

Poor Communication or Limited Customer Reviews

Communication is key throughout the rebuild process. Companies that are slow to respond, avoid answering questions, or fail to provide updates can leave you frustrated and uncertain. Limited or negative customer reviews are another warning, look for companies with a proven track record of satisfied clients.

By staying alert to these red flags, you can avoid costly delays, subpar work, and ongoing headaches. Choosing a company that demonstrates transparency, quality, and professionalism is the best way to ensure your turbo performs reliably for years to come.

Remanufactured Turbos from HD Turbo

Choosing the right turbo remanufacturing company is about more than just price, it’s about quality, speed, and support. At HD Turbo, we rebuild each turbo with precision, using high-quality components, expert balancing, and advanced tools to restore performance to OEM standards. Every unit undergoes thorough testing, including checks for oil leaks, ensuring it performs as reliably as a brand-new turbocharger. With a 12-month unlimited mileage warranty, you can have peace of mind knowing your investment is protected.

If you’re ready to get your turbo back to peak performance quickly and reliably, call HD Turbo at (847) 258-3785 to learn more about our professional remanufacturing process and industry-leading support.

Mission

We have ONE GOAL – provide you with a MORE POWERFUL and MOST RELIABLE turbocharger for years to come.

High Quality Products

Heavy-duty turbochargers are high-quality, produced in a state-of-the-art facility capable of balancing turbo components as well as whole rotating assemblies. Strict quality control.

Great Team

Our dedicated and detail-oriented team is always happy to help you – don’t hesitate to reach out with questions or comments.

Authorized Dealer

Authorized Dealer