Diesel engines are built for power, durability, and efficiency, but even the toughest engines rely on a healthy turbocharger to perform at their best. The turbo is the heart of your diesel’s performance, boosting power and improving fuel efficiency, but it’s also one of the components most prone to wear if not properly maintained. In this guide, we’ll show you practical tips and expert strategies to help your diesel turbo last longer, stay reliable, and keep your engine running smoothly for miles to come.

Understand How Your Turbo Works

Before you can make your diesel turbo last longer, it helps to understand how it works and what can cause it to wear prematurely.

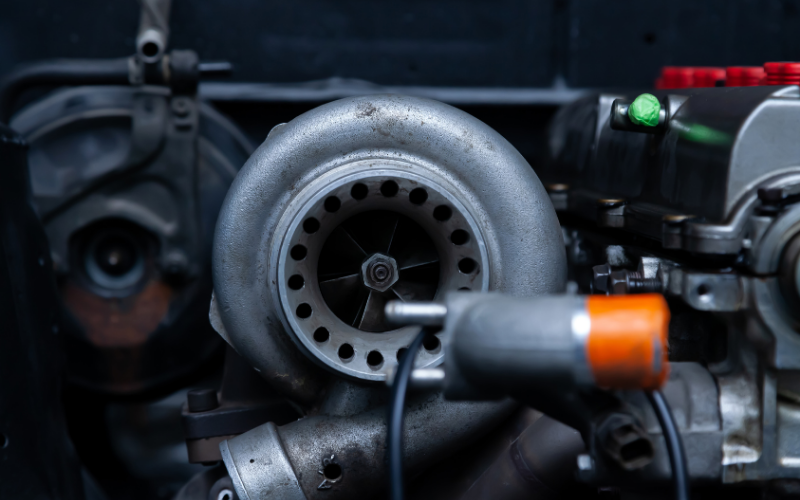

At its core, a turbocharger is a high-speed air pump that forces more air into the engine’s combustion chamber. By increasing airflow, the turbo allows the engine to burn fuel more efficiently, producing more power and better fuel economy. This makes it a critical component in your diesel engine’s performance, but also one that operates under extreme conditions.

Heat, pressure, and lubrication are the three main factors that affect a turbo’s longevity. Turbochargers spin at tens of thousands of revolutions per minute and are exposed to exhaust gases that can exceed 1,000°F. Without proper cooling and high-quality lubrication, the internal bearings and seals can wear out quickly. Excessive pressure from aggressive driving or over boosting can also strain the turbo, while contaminated or degraded oil can accelerate wear.

Knowing the signs of stress or early wear can save you from costly repairs. Keep an eye (and ear) out for unusual noises like whining or rattling, excessive smoke from the exhaust, or a noticeable drop in engine performance. Catching these issues early allows you to address the root cause before the turbo suffers serious damage.

Prioritize Proper Oil Maintenance

One of the most important ways to extend the life of your diesel turbo is through consistent, high-quality oil maintenance. Your turbo relies on engine oil not just for lubrication, but also for cooling the spinning components. Neglecting oil care can lead to increased friction, overheating, and ultimately premature turbo failure.

Start by using the oil recommended by your engine manufacturer, high-quality diesel engine oils are specifically formulated to handle the heat and pressure your turbo generates. Stick to regular oil change intervals, and don’t wait for the “change oil” light to come on. Dirty or degraded oil can leave deposits on turbo bearings, restricting airflow and causing wear.

Monitoring oil levels and checking for contamination is also crucial. Look for signs of metal shavings, unusual discoloration, or a burnt smell, which could indicate internal engine issues affecting your turbo. Additionally, ensure that your oil cooling and filtration systems are functioning properly, this helps prevent overheating and keeps your turbo spinning smoothly for the long haul.

Warm-Up and Cool-Down Routines

How you drive your diesel engine plays a big role in turbo longevity, and that starts with proper warm-up and cool-down routines. A turbo operates under extreme heat and stress, and sudden changes in temperature can cause metal components to expand and contract too quickly, leading to premature wear or even cracks.

Before hitting high RPMs, allow your engine a few minutes to warm up. This ensures that oil is circulating fully, lubricating the turbo’s bearings, and that the metal components have reached an optimal operating temperature. Similarly, don’t shut your engine off immediately after a hard drive or heavy towing. Letting your diesel idle for a minute or two allows the turbo to cool gradually, preventing “hot shutdown” damage where residual heat can burn the oil inside the turbo.

Adopting these simple habits, starting gently and finishing with a brief cooldown, can dramatically reduce stress on your turbo and extend its lifespan.

Keep the Air Intake and Exhaust System Clean

A diesel turbo can only perform well if it has a clear path for airflow. Dirty or clogged air intake systems and exhaust components force your turbo to work harder, increasing stress and wear. Regular maintenance of these systems is essential for long-term turbo health.

Start with your air filter: inspect it regularly and replace it as needed. A clogged or dirty filter reduces airflow, allowing dust and debris to enter the turbo, which can damage the delicate turbine blades. Intercoolers and hoses should also be checked for leaks, cracks, or blockages, as any restriction in airflow can compromise performance and increase turbo strain.

Even the exhaust system plays a role. Ensure there are no leaks, soot buildup, or restrictions that force the turbo to operate under excessive backpressure. Keeping both the air intake and exhaust system clean not only helps your turbo last longer but also improves engine efficiency and fuel economy.

Avoid Overloading the Turbo

While diesel engines are built for power, pushing your turbo beyond its limits can drastically shorten its lifespan. Overloading the turbo occurs when the engine is subjected to excessive boost, high RPMs, or heavy towing without allowing the system to operate within safe parameters.

Start by avoiding aggressive acceleration immediately after starting the engine. Give your turbo a moment to spool up naturally. Similarly, if you’re towing or carrying heavy loads, be mindful not to exceed the manufacturer’s recommended limits. Over boosting or consistently running the engine at maximum load creates extreme heat and pressure, which can damage the turbo’s bearings and seals over time.

Adopting smoother driving habits and respecting your turbo’s limits not only protects this critical component but also improves fuel efficiency and overall engine longevity.

Watch for Warning Signs Early

Catching turbo issues early can save you from costly repairs or a complete replacement. Turbos operate under high heat and speed, so any signs of stress or malfunction should be addressed immediately.

Listen and watch for unusual noises, such as whining, whistling, or rattling sounds coming from the engine. These can indicate worn bearings or damaged turbine blades. Excessive smoke from the exhaust, especially black, blue, or white smoke, can also signal turbo problems, such as oil leaks or improper combustion. Additionally, a noticeable drop in engine power or sluggish acceleration may point to reduced turbo efficiency.

Paying attention to these early warning signs and addressing them promptly can prevent minor issues from escalating into major turbo failures, saving both time and money in the long run.

Routine Inspections and Professional Maintenance

Even with diligent care, turbos are precision components that benefit from regular inspections by a professional. Routine checks help identify wear, leaks, or other issues before they become serious problems.

During inspections, technicians will often check for excessive shaft play, worn bearings, oil leaks, or damage to turbine blades. They can also assess the overall health of your engine’s oil and air systems, which directly affect turbo performance. Scheduling periodic professional maintenance ensures that small issues are caught early, keeping your turbo operating efficiently and extending its service life.

Remember, preventive maintenance is always more cost-effective than reactive repairs. A timely inspection can mean the difference between a minor adjustment and a full turbo replacement.

Additional Tips for Longevity

Beyond regular maintenance and careful driving habits, there are several extra steps you can take to help your diesel turbo last longer.

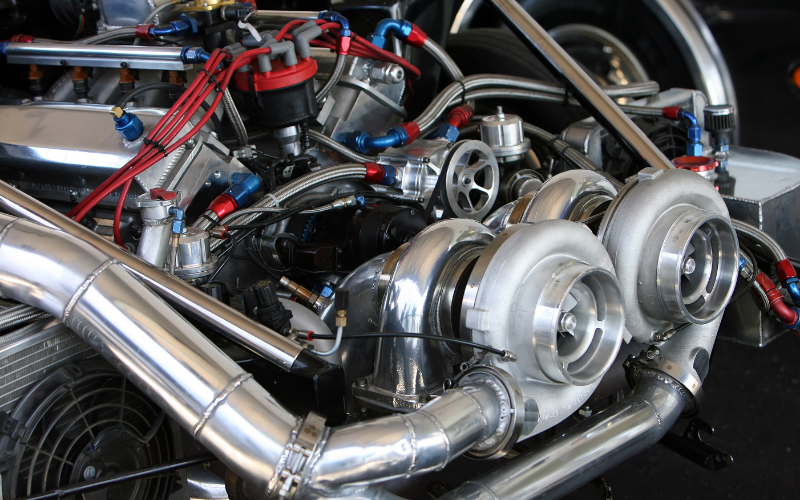

Using high-quality fuel and fuel additives can reduce carbon buildup and help keep your turbo and engine cleaner. Upgrading turbo components, such as more durable bearings or improved intercoolers, may also enhance longevity, especially if you frequently tow or drive under heavy load conditions. Additionally, keeping an eye on engine temperature and boost levels ensures your turbo isn’t being overworked.

Small, consistent actions, like monitoring your engine and fuel quality, making minor upgrades when necessary, and avoiding extreme conditions, can significantly extend the life of your turbo and maintain optimal engine performance.

Remanufactured Turbochargers from HD Turbo

A diesel turbo is a high-performance component that requires proper care to maximize its lifespan. By understanding how your turbo works, maintaining clean oil and air systems, warming up and cooling down correctly, and paying attention to warning signs, you can keep your turbo running efficiently for years.

Even with the best maintenance, turbos can eventually wear out, which is where high-quality replacements become essential. HD Turbo offers precision remanufactured diesel turbochargers that meet or exceed OEM specifications, ensuring your engine performs reliably and efficiently. If it’s time to replace or upgrade your turbo, call HD Turbo at (847) 258-3785 to find a remanufactured turbocharger that fits your engine perfectly and keeps your diesel running at its best.

Mission

We have ONE GOAL – provide you with a MORE POWERFUL and MOST RELIABLE turbocharger for years to come.

High Quality Products

Heavy-duty turbochargers are high-quality, produced in a state-of-the-art facility capable of balancing turbo components as well as whole rotating assemblies. Strict quality control.

Great Team

Our dedicated and detail-oriented team is always happy to help you – don’t hesitate to reach out with questions or comments.

Authorized Dealer

Authorized Dealer