When a turbocharger starts to show signs of wear, replacing it with a brand-new unit isn’t always the most practical or sustainable solution. However, replacing your worn-out turbo with a remanufactured turbocharger is a cost-effective solution.

Through a detailed process of disassembly, inspection, cleaning, and precision rebuilding, used turbochargers can be restored to like-new performance at a fraction of the cost. In this blog, we’ll walk you through how turbo remanufacturing works and why it’s a smart option for both fleets and everyday drivers. If you’re curious about how old turbochargers get a second life, this guide is for you.

What are Remanufactured Turbochargers?

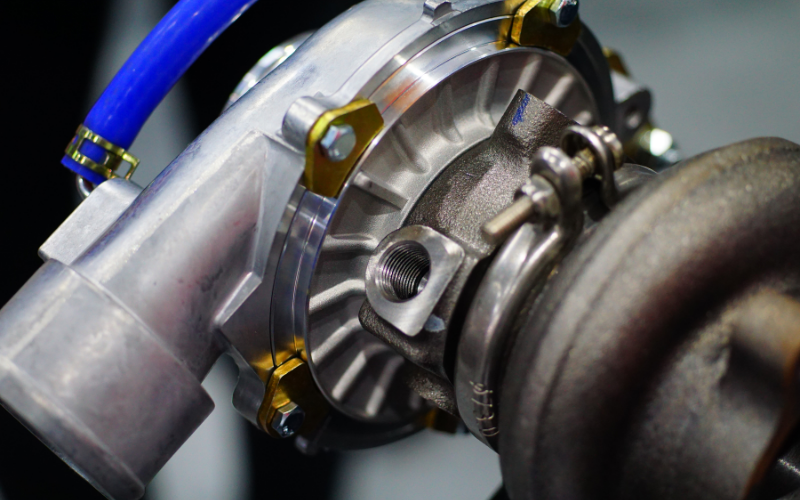

Remanufactured turbochargers are used turbochargers that have been professionally restored to meet or exceed original equipment (OE) specifications. Rather than simply repairing or replacing a faulty part, remanufacturing involves completely disassembling the turbocharger, thoroughly inspecting and cleaning all components, replacing worn or damaged parts (like bearings, seals, and sometimes the compressor wheel), and reassembling the unit with precise balancing and testing.

What are the Benefits of a Remanufactured Turbocharger?

There are several benefits to buying a remanufactured turbocharger from the cost compared to a new turbocharger to the level of performance. The following are the main advantages:

- Cost savings: Remanufactured turbochargers typically cost 30–50% less than new OEM units. You get near-new performance without the premium price tag, making them ideal for budget-conscious vehicle owners and fleet operators.

- Like-new performance: A professionally remanufactured turbo is rebuilt to meet or exceed original equipment specifications. Critical components like bearings, seals, and thrust parts are replaced, and the unit is precisely balanced and tested to ensure performance and reliability.

- Environmentally friendly: Remanufacturing reuses the main housing and other serviceable parts, which reduces waste in landfills, energy used in manufacturing, and the consumption of raw materials. This makes remanufactured turbos a sustainable alternative to buying new.

- Faster availability: Compared to some new turbos that may be on back order or have long lead times, remanufactured units are often readily available, especially for older or less common vehicles.

- Warranty coverage: Reputable remanufacturers offer warranties comparable to new units, giving buyers confidence in the product’s durability and performance.

- OEM compatibility: Most remanufactured turbochargers are built using original housings and follow OEM specs, ensuring a perfect fit and seamless integration with your engine’s system.

- Support for older vehicles: For vehicles no longer supported by the manufacturer, remanufactured turbos can be a lifesaver, offering a reliable solution when new units are no longer produced.

Turbocharger Remanufacturing Process

The remanufacturing process for turbochargers includes several meticulous steps that help ensure optimal performance and reliability. The following are the main steps that professionals take to remanufacture turbos so that they perform at the same level you can expect from new turbos.

Inspection and Evaluation

The first step is to thoroughly inspect and evaluate the condition of the turbocharger. With this inspection, technicians can assess the wear and damage to the parts and determine which of the damaged parts can be reused, repaired, or replaced.

During the inspection, every part is examined including the shaft, bearings, housing, turbine, and compressor wheels. The aim is to preserve as many original parts as possible while maintaining top quality and performance.

Turbocharger Disassembly

Once the inspection is complete, the turbocharger is carefully disassembled. Every part is removed, documented, and organized to ensure that the turbocharger can be properly reassembled. The first step of the disassembly is to separate the main sections of the turbocharger including the center housing, turbine housing, and compressor housing. Each section is then further disassembled as delicate components such as the compressor wheel, turbine shaft, seals, and bearings are removed.

Turbochargers are disassembled using special tools to avoid causing additional damage to the more delicate parts. Strict safety protocols are also followed to protect against hazardous materials such as residual oil and metal particles.

Cleaning and Preparation

Once the parts are disassembled, each part is thoroughly cleaned to remove carbon deposits, oil residue, and any accumulated debris. Residue and debris build up within the turbocharger components over time as they are exposed to high heat and harsh conditions. Removing the contaminants and debris with thorough cleaning allows for more accurate inspection and assessment of the parts.

Turbocharger components may be cleaned using one of the following methods:

- Chemical baths: Chemical solutions can remove carbon deposits and grease.

- Sandblasting: Abrasive chemicals are used to clean non-delicate parts like housing and metal surfaces.

- Ultrasonic cleaning: This process is used to remove contaminants from small and intricate components by using high-frequency sound waves in a cleaning solution.

The cleaning method is chosen based on the component and level of contamination. Each part is inspected after cleaning to look for hidden damage.

Component Inspection and Testing

The cleaned components are once again inspected to check their alignment, dimensions, and structural integrity. Technicians will make sure parts such as the compressor wheel and turbine shaft meet manufacturer specifications for balance, thickness, and diameter using precision measurement tools.

During this step, technicians will inspect the following:

- Turbine shaft: Checked for scoring, cracks, and proper alignment

- Compressor wheel: Inspected for chips or bends that may impact performance

- Housing: Checked for warping and cracks that could affect performance or lead to leaks

- Bearings and seals: Checked for wear because these parts tend to wear down first in a turbocharger

The goal of the inspection after cleaning is to determine which parts are reusable, which parts can be restored, and which parts must be replaced.

Replacing and Upgrading Components

Components that have experienced extensive wear or damage will be disposed of and replaced with new parts to ensure performance and efficiency. The parts that are most often replaced due to excessive wear include cases, seals, and bearings that are exposed to constant friction. The damaged parts are replaced with parts that meet or exceed the original specifications.

For some rebuilds, technicians may also upgrade certain parts to improve the efficiency and durability of the turbocharger. The parts that are commonly upgraded include:

- Bearings: Upgraded bearings reduce friction for smoother operation.

- Turbine wheels: Technicians may upgrade turbine wheels with replacements made from materials that can better resist heat.

Reassembly

Once all the components have been cleaned, repaired, or replaced, it is time to reassemble the turbocharger. The reassembly must be done carefully to ensure that everything is in alignment for maximum performance. The exact specifications are followed for each opponent so that the parts fit back together properly.

Testing and Calibration

After the turbocharger is reassembled, it must be calibrated and rigorously tested to make sure it meets necessary performance standards. The testing process includes these steps:

- Airflow tests: These tests simulate engine conditions to ensure that the right boost pressure is generated by the turbocharger.

- Pressure and temperature tests: These tests ensure that the turbocharger can withstand operational stresses without overheating or leaking.

- Dynamic balancing: The rotating assembly is balanced to avoid vibrations at high RPMs.

Once the turbocharger passes these tests, it is calibrated to the specifications of the original manufacturer or the requirements of the customer. This includes fine-tuning components such as the wastegate actuator for maximum performance.

Quality Control and Packaging

Once all testing is successfully completed, the turbocharger undergoes a thorough final inspection to ensure it complies with industry benchmarks and remanufacturing requirements. Technicians meticulously record the condition and precise details of the remanufactured turbocharger, keeping a comprehensive log of the work conducted.

Next, the turbocharger is securely packaged to shield it from potential damage during transportation or storage. Adequate packaging plays a critical role, as even minor impacts or surface marks could compromise its functionality or reduce its durability.

Remanufactured Turbochargers from HD Turbo

Remanufactured turbochargers offer a smart, sustainable, and cost-effective solution for restoring engine performance without the high price of new units. With a rigorous process that includes inspection, cleaning, precision rebuilding, and thorough testing, remanufactured turbos can deliver like-new reliability and efficiency. Whether you’re managing a fleet or maintaining a personal vehicle, choosing a professionally remanufactured turbocharger means saving money, reducing waste, and getting back on the road with confidence. When done by experienced technicians, a remanufactured turbo isn’t just a second-hand part, it’s a second chance at peak performance.

HD Turbo specializes in remanufacturing and rebuilding turbochargers with unparalleled quality. We offer a wide range of services, including turbocharger restoration, calibration, performance upgrades, and precision repairs, all crafted to maximize your vehicle’s efficiency and lifespan.

Our cutting-edge facility allows us to precisely balance turbocharger components and complete rotating assemblies. This dedication to precision makes HD Turbo a leader in advanced turbocharger remanufacturing within the region. We use premium-grade parts and adhere to rigorous quality control procedures, guaranteeing that our remanufactured turbochargers and components deliver top-notch performance and reliability. Whether you need a comprehensive rebuild or repair, HD Turbo provides customized solutions to align with your performance needs.

Mission

We have ONE GOAL – provide you with a MORE POWERFUL and MOST RELIABLE turbocharger for years to come.

High Quality Products

Heavy-duty turbochargers are high-quality, produced in a state-of-the-art facility capable of balancing turbo components as well as whole rotating assemblies. Strict quality control.

Great Team

Our dedicated and detail-oriented team is always happy to help you – don’t hesitate to reach out with questions or comments.

Authorized Dealer

Authorized Dealer